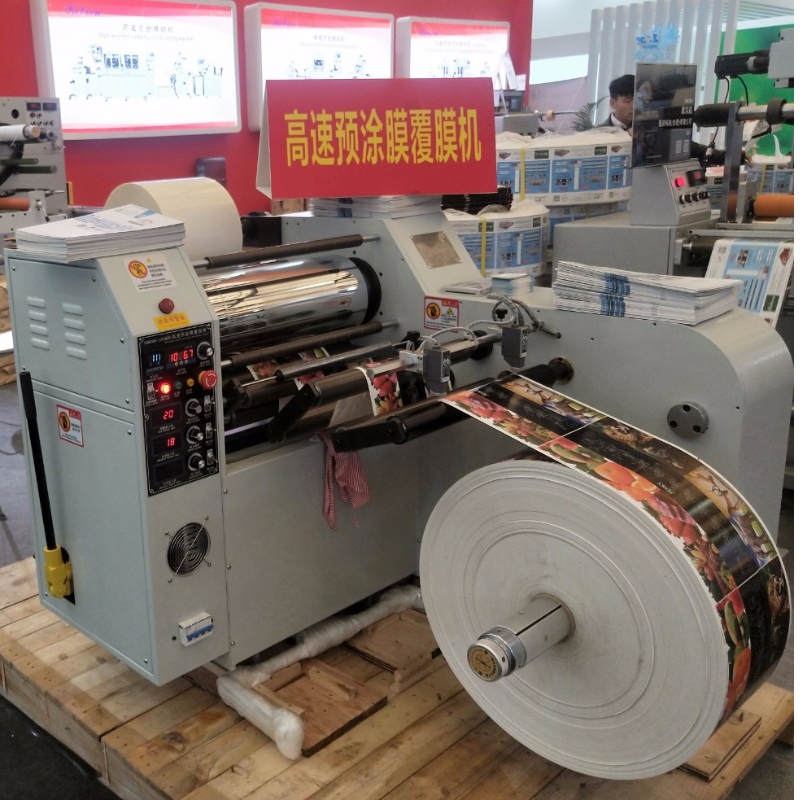

Five Advantages Of Products

- The rubber drum is made of imported silica gel material, which is non-adhesive to ink and paper under high temperature and high pressure

- Automatic tension control, random automatic adjustment of film tension

- Desktop automatic deviation correction system, deviation correction effect is more ideal

- Adopt oil pressure device to provide more compound pressure for the plastic roller, which is enough to meet the pressure demand of various pre-coated films

- Label unwinding device (this has been granted the national patent, patent number: 2015208631878)

Product Details

Dongguan Weineng Machinery Technology Co., Ltd. is specialized in the production of automatic rectifying film laminating machine, high-speed pre-coating film laminating machine, roll-to-roll label hot laminating machine, roll-to-roll embossing machine, glazing film laminating machine, automatic multi-functional cutting table and other printing peripheral equipment.Strong technical force, advanced technology, the use of high precision parts, products sold throughout the country and exported overseas.Automatic rectifying laminating machine is mainly applicable to a variety of synthetic paper, pearlite film, Xiao Yinlong, bright silver, PET, PP, cardboard, coated paper drum and other materials.Eliminate warping and wrinkling, save energy and protect environment, operate stably.Performance Features:

*. The rubber drum is made of imported silica gel material, which is non-adhesive to ink and paper under high temperature and high pressure;

*. Automatic tension control, random automatic adjustment of film tension;

*. Desktop automatic deviation correction system, deviation correction effect is more ideal;

*. Adopt oil pressure device to provide more compound pressure for the plastic roller, which is enough to meet the pressure demand of various pre-coated films;

*. Label unwinding device (this has been granted the national patent, patent number: 2015208631878

Energy saving advantage

*Can make self-adhesive light film cost saving about 45%

*Can make adhesive dumb film cost saving about 55%

*Can make adhesive laser film cost saving about 60%

*Can be a variety of synthetic paper, PVC, PET, PP drum materials such as perfect coating

Contact Us

Dong Guan Weineng Machinery Technology Co., Ltd.

Contact Person: Eric zhong

Department: Sales Department

Post: Sales Manager

Telephone: +86-18575327678

Landline: 0769-89771779

Company Address: No. 8 Building, Sixth Wusong Street, Yuwu Industrial Zone, Dongcheng District, Dongguan City, Guangdong Province, China

Website: www.wn-machine.com