Five Advantages Of Products

- The machine is made of super large mirror steel roller (210) Ø oil temperature heating design, speed is quick, save electricity constant temperature

- The rubber drum is made of imported silica gel material, which is non-adhesive to ink and paper under high temperature and high pressure

- Mechanical spring pressure control tension, no material automatic stop, compact structure, easy operation

- Hand expansion shaft with measuring scale is adopted for both loading and unloading, accurate and convenient

- Adopt oil pressure device to provide more compound pressure for the plastic roller, which is enough to meet the pressure demand of various pre-coated films

Product Details

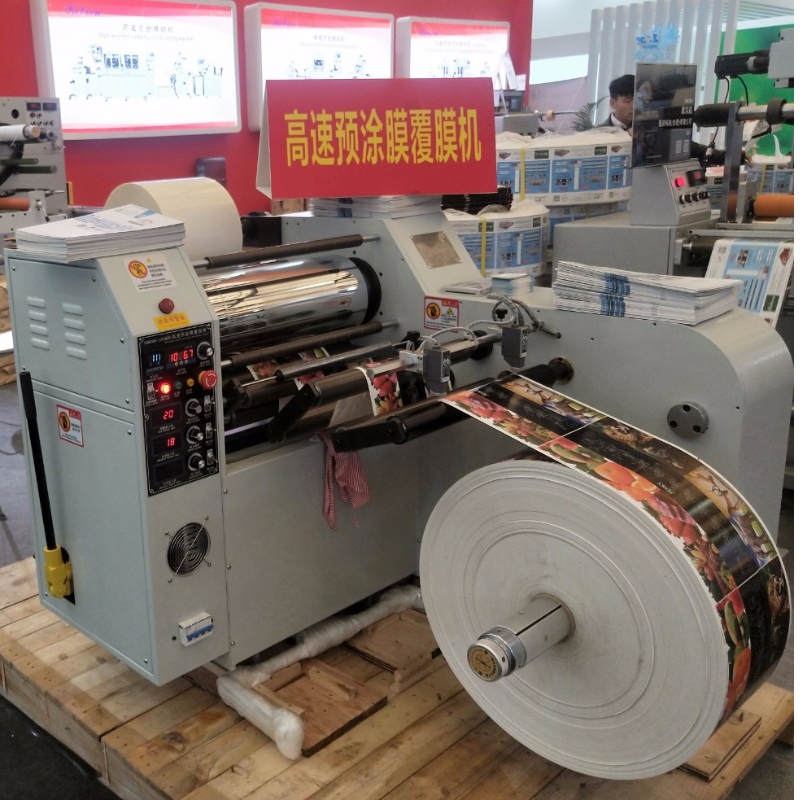

Coil to coil laminating machine is suitable for all kinds of drum material special laminating machine, is special composite light, dumb, pre-coated film and anti-counterfeiting laser film.It is mainly applicable to the post-press laminating processing industry of all kinds of roll materials of adhesive labels.The product than the traditional adhesive cold plastic laminating cost reduction of at least 45% above the cost, and avoid 400 meters need to change the film trouble, after covering the product adhesion, high transparency, strong durability;The composite hot roller adopts electric heating mode of oil medium, which can heat up quickly, keep constant temperature for a long time, and the surface temperature is uniform. It is equipped with high-precision oil temperature heating system to automatically control and stabilize the temperature.

The main engine has the functions of frequency conversion, automatic temperature control and adjustment instrument, automatic stop without material, etc.The machine has compact structure, convenient operation, high efficiency, safe and reliable, it is a high-efficiency economic benefit and practical machine in the era of low profit in the adhesive industry at present.Roll to roll laminating machine is mainly suitable for paper, coated paper, synthetic paper, PP material such as drum perfect draping.Energy saving and environmental protection, stable operation.

Performance characteristics:

*. The machine is made of super large mirror steel roller (210) Ø oil temperature heating design, speed is quick, save electricity constant temperature;

*. The rubber drum is made of imported silica gel material, which is non-adhesive to ink and paper under high temperature and high pressure;

*. Mechanical spring pressure control tension, no material automatic stop, compact structure, easy operation;

*. Hand expansion shaft with measuring scale is adopted for both loading and unloading, accurate and convenient;

*. Adopt oil pressure device to provide more compound pressure for the plastic roller, which is enough to meet the pressure demand of various pre-coated films.

Contact Us

Dong Guan Weineng Machinery Technology Co., Ltd.

Contact Person: Eric zhong

Department: Sales Department

Post: Sales Manager

Telephone: +86-18575327678

Landline: 0769-89771779

Company Address: No. 8 Building, Sixth Wusong Street, Yuwu Industrial Zone, Dongcheng District, Dongguan City, Guangdong Province, China

Website: www.wn-machine.com